Stainless hlau hnab lim tsev hnab lim cartridge lim rau petrochemical kev lag luam

piav qhia luv luv:

Stainless hlau hnab lim tsev hnab lim cartridge lim rau petrochemical kev lag luam

Keeb kwm: Suav teb

Khoom siv: A3, # 20 steel, SS304 (rau dej tshiab), SS316 (rau dej hiav txwv)

Lim qhov tseeb: 0.5-1000micron

inlet thiab qhov hluav taws xob: 1-14inch lossis customized

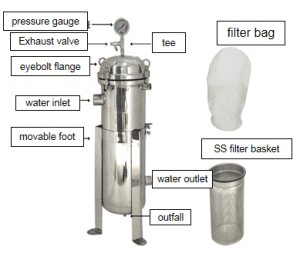

hnab lim vaj tsev ua haujlwm txoj cai

Lub hnab lim yog siv dav siv rau kev lim dej, nws tuaj yeem tshem tawm cov khoom sib txawv ntawm cov kua, thiaj li ua tiav cov kua lim, lim dej, sib cais, rov qab lub hom phiaj. Raws li tus nqi ntws, koj tuaj yeem siv ntau lub hnab hauv ib lub hnab hauv tsev. Ua ntej, cov kua nkag mus rau hauv lub vaj tsev los ntawm cov inlet, uas yuav muab tso rau hauv sab los yog saum toj, thiab ces ntws mus rau hauv lub hnab lim uas yog braced los ntawm pob tawb. .Vim qhov cuam tshuam ntawm cov kua dej, lub hnab yuav txuas ntxiv thiab cov kua tau sib npaug los ntawm lub hnab thiab ntws tawm ntawm lub qhov hluav taws xob cov yeeb nkab.Impurities raug kaw hauv lub hnab, cov txheej txheem pom tau tiav.Thaum koj hloov lossis ntxuav lub hnab. , tsuas yog loosen lub ntsia liaj qhov rooj, teb tes log nqa lub hau, thiab tau lub hnab.

hnab lim tsev festures:

Lub hnab lim yog cov khoom siv lim dej ntau yam nrog kev ua haujlwm yooj yim thiab hloov tau yooj yim, txuag hluav taws xob, ua haujlwm siab, kaw haujlwm thiab muaj zog siv tau.

Lub hnab lim tau txais kev txhawb nqa los ntawm cov pob tawb hlau hauv, cov kua dej ntws los ntawm qhov nkag, thiab tom qab ntawd ntws tawm ntawm qhov hluav taws xob tom qab lim los ntawm lub hnab lim. Cov impurities raug cuam tshuam rau hauv lub hnab lim. Yuav siv tau tom qab hloov lub hnab lim.

Hnab nyob Internal qauv

1. Txhua lub hnab ntim khoom muaj qhov sib cais ntawm cov khoom siv xauv uas tsis muaj qhov cuam tshuam rau sab.

2. Integrated tsim ntawm precision tsis distortion.

3. Integrated precision nrog lifting ntaus ntawv.

4. O-ring foob, siab zog thiab ceev bolts.

Lim hnab khoom

hnab lim vaj tsev daim ntawv thov:

1. Kev lag luam khoom noj khoom haus thiab dej haus: npias, cawv, cawv, cawv, cawv, cawv, kua txiv hmab txiv ntoo, dej fwj, tshuaj yej dej qab zib, kua mis, syrup, khoom noj siv mis, khoom noj khoom haus additives, dej pom kom meej cov txheej txheem thiab CIP.

2. Petrochemical kev lag luam: txhua yam ntawm lubricants thiab roj, kua nplaum, tshuaj fiber ntau raug txheej txheem ntawm ntau yam tshuaj tau lim.

3. Roj thiab roj kev lag luam: amine desulfurization, lub cev qhuav dej flux lim, roj teb dej, ua tiav kua pom.

4. Lub tsheb pleev xim, kev lag luam pleev xim: xim pleev xim, xim electrophoretic, ua ntej kev kho dej, xim thiab xim cov ntaub ntawv raw thiab hnyav pom

5. Textile, luam ntawv thiab dyeing, ntawv ua kev lag luam: spinning kua, dyes, flux, dej, additives, adhesives lim.

6. Kev lag luam roj thiab xab npum: polishing purification ntawm edible roj, xab npum raw cov ntaub ntawv thiab dej pom.

7. Pharmaceutical kev lag luam: ntau yam tshuaj intermediates, tshuaj raw khoom, hnyav pom.

8. Kev lag luam hluav taws xob thiab electroplating: ntau yam ntawm cov tshuaj plating thiab dej pom.

9. Machining kev lag luam: ntau yam kev txiav cov kua, coolant thiab ntxuav cov kua pom.

10. Lwm yam kua pom.